Maze without a Minotaur

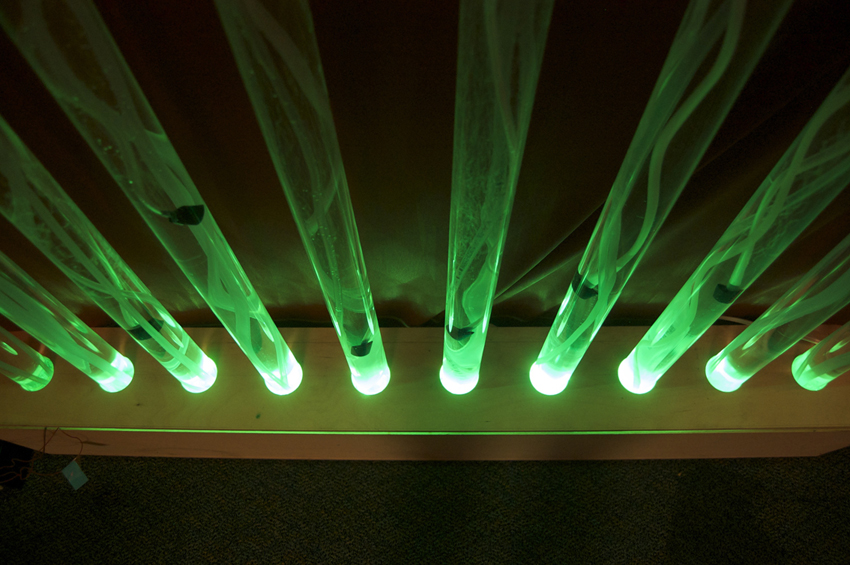

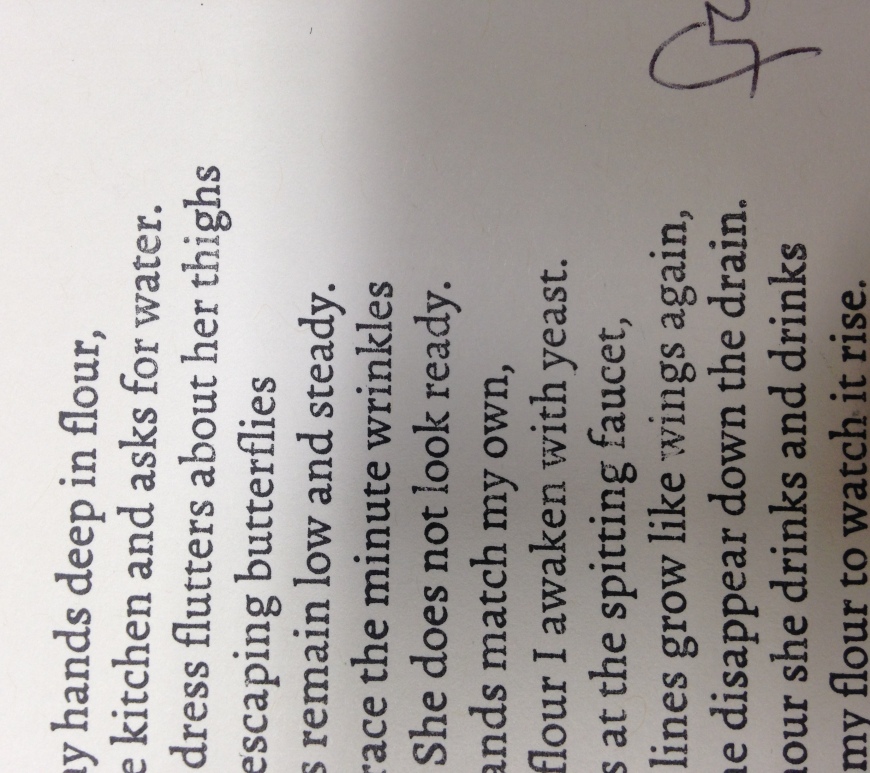

Happy Halloween! My housemates and I fulfilled a long-term dream of mine to create a completely pitch-black maze. It wasn’t meant to be inherently scary — no ghouls jumping out at you. Just dark and alone. Some could find it peaceful. I found it a to be a rush, scary yet intriguing. I framed the maze with this poem by Dana Gioia which touches on this … Continue reading Maze without a Minotaur